- Vacuum Rubber Press

- High Speed Rubber Press

- Rubber Injection Molding Machine

- Rubber Production Line

- Rubber Mixing Mill

- Rubber Press

- Conveyor Belt Splicing Machine

- EVA Foam Press and Others

- Tyres Machinery

- Four-Column Hydarulic Press

- Waste Tire Processing Machine

- Rubber Extruder And Strainer

- Rubber Cutting Machine

- Rubber Tiles Mould

- Dispersion Kneader

- E Type Rubber Press

- Silicone Rubber Products

- Environmental Protection Solid Tires

-

Rail Mold Rubber Molding Press Machine

Rail Mold Rubber Molding Press Machine with Highly Automatic Program

-

Vertical Rubber Injection Molding Press Machine

200T Rubber Injection Molding Press Machine with 3RT.

-

High Speed Rail Mold Open Hydraulic Molding Press Machine

1.This type of machine is suitable to be used for double mold plates. It is capable of high speed production. 2.For the rail mold openning, the openning angle is up to 90 degree. It is very convenient to operate. 3.Slow moving speed is available for alignment more safe and more accurate. 4.High force employs dual pressure and each oil system is designed separately. It is consistent. quiet and low frequency of malfunctions. Two shafts can be operated simultaneous.

-

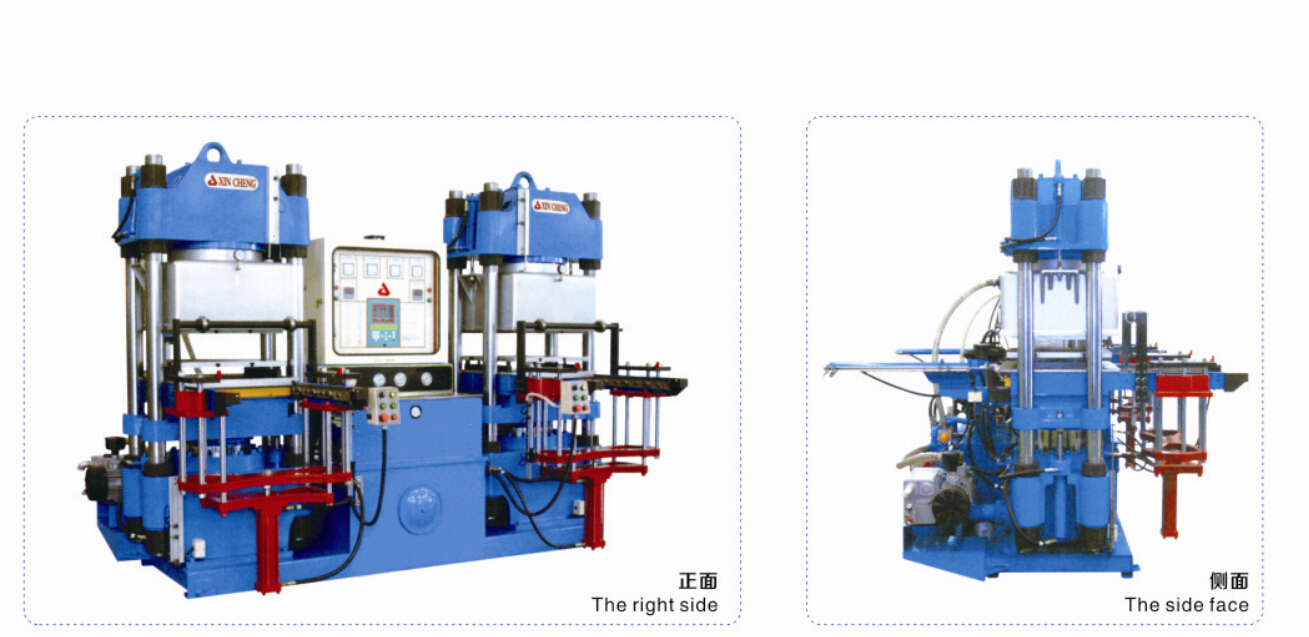

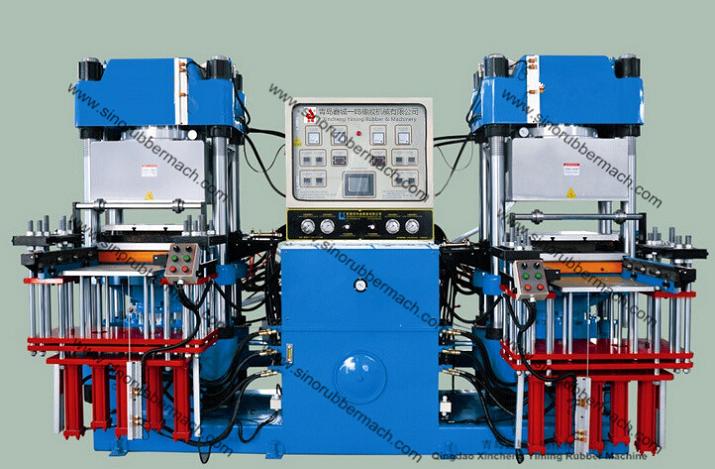

2RT Front Top Mold Open Hydraulic Molding Press Machine

1.This type of machine is multi-functional, because it is suitable to be used for top opening double or triple mold plates; 2.High force employs dual pressure and each oil system is designed separately. It is consistent. quiet and low frequency of malfunctions. Two shafts can be operated simultaneous; 3.Slow moving spee is available for alignment more safe and more accurate; 4.Molds can be precisely positioned. A 100% safety design for positioning is available to prevent molds from damage. 5. The speed to open close the mold is adjustable. It is very accurate and reliable.

-

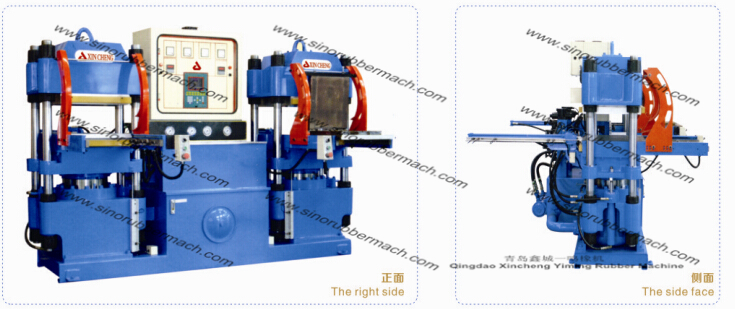

3RT Front Top Mold Open Hydraulic Molding Press Machine

1. The 3RT surpasses the traditional top opening mold that can be used fot the triple or four mold plates with the design of opening mold and pushing out the mold in between; 2. The opening mold can be adjsted by the software with separate opening, separate pushing out the mold in between, continous opening and continuous pushing out the mold in between.