- Vacuum Rubber Press

- High Speed Rubber Press

- Rubber Injection Molding Machine

- Rubber Production Line

- Rubber Mixing Mill

- Rubber Press

- Conveyor Belt Splicing Machine

- EVA Foam Press and Others

- Tyres Machinery

- Four-Column Hydarulic Press

- Waste Tire Processing Machine

- Rubber Extruder And Strainer

- Rubber Cutting Machine

- Rubber Tiles Mould

- Dispersion Kneader

- E Type Rubber Press

- Silicone Rubber Products

- Environmental Protection Solid Tires

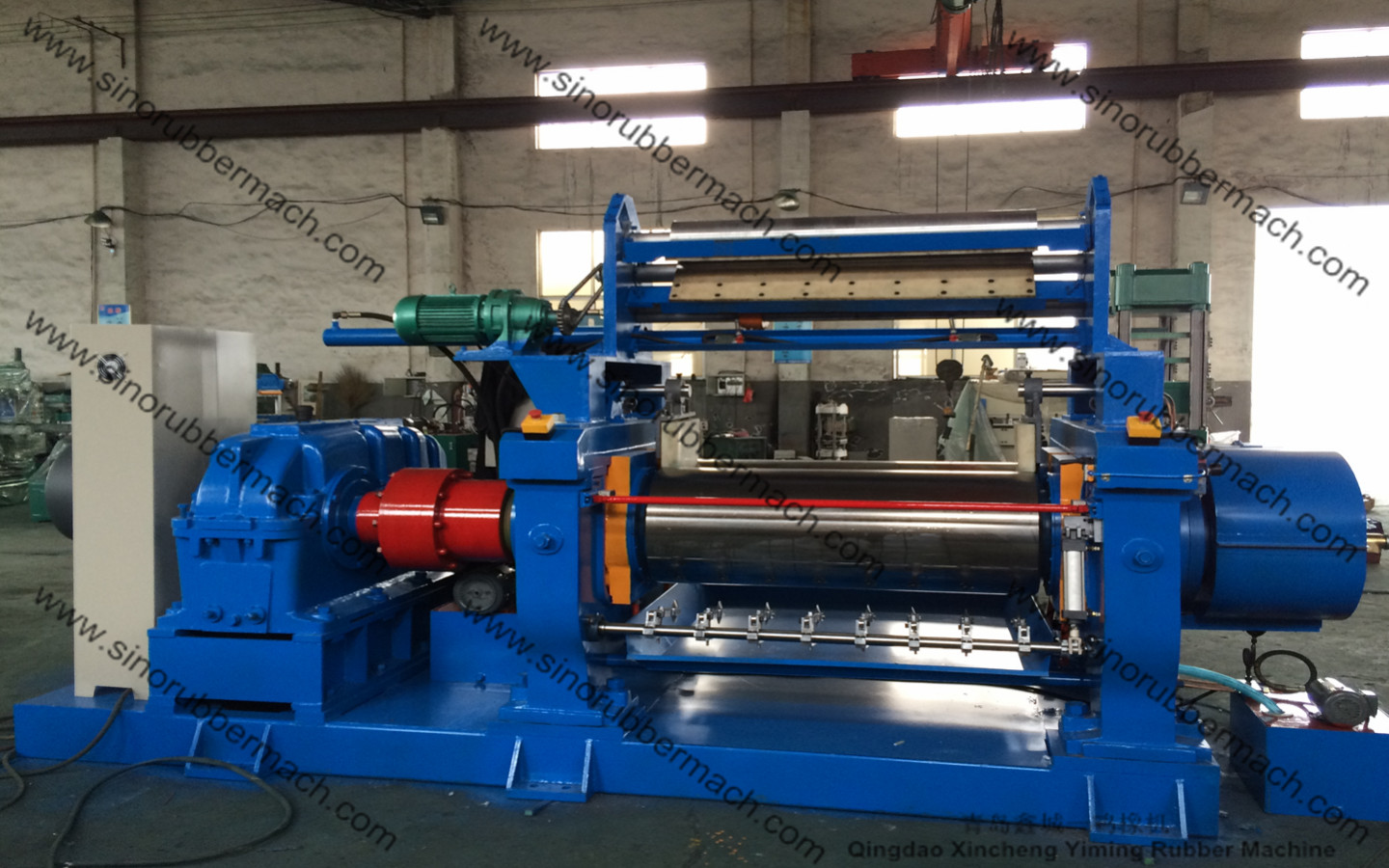

XK-450 Two-Roll Mixing Mill(with blender)

Open Rubber Mixing Mill(with stock blender)

Type XK-450

Roller Material: Chilled Cast Iron

Working diameter of roller(mm) ¦µ450

Working length of roller(mm) 1200

Working speed(m/min) (front roller) 24.5 (constant speed)

Friction ratio of front and rear roller 1:1.27

Capacity per.batch(kg) 25-50

Roll nip adjustment range and mode Electrical roll nip control 0.5mm-15mm

Motor power of electrical nip control 0.75KW¡Á2=1.5KW

Mill Cheek control mode by manual

Main Motor Power(KW) 55

Bearing Case Rolling Bearing

Cooling medium Cooling water

Lubricating type use oil for lubrication

Reducer type D Shaped Hard Teeth Gear Reducer

Host Machine Overall size (L¡ÁW¡ÁH) About 5200¡Á2380¡Á1870mm

Net weight(kg) About 11050

Gross Weight(kg) About 12000

MEASUREMENT About 24CBM

Power supply AC380V 50HZ 3PH

The basement process Welding structure

Main Using scope Be used for mixing rubber material.

H.S Code 8477.8000

Notes The 2 security bars been installed at the front of front-roller & rear of rear-roller.

For mill stock blender details:

Traction roll diameter(mm): ¦µ160

Traction roll line speed(m/min): 2.7-26.67

Swing times (times/min): 2.5

Swing range(mm): 900

Press roll moving(mm): 72

Traction roll motor power(KW): 2.2

Power supply AC380V 50HZ 3PH

Blender weight(kg): About 1000

Addition:

2 security bars.

System for cutting rubber like picture in attachment but with 8 knife distance between them 80 mm.